閥門分類

本真空截止閥按JB/T3595標準(zhǔn)設計製造,滿足電站設備配套使用要求。設計了真空密封(fēng)結構填料室,隔離真空可靠(kào)。閥杆經調(diào)質及表麵氮化(huà)處理,有良好的抗腐蝕性,抗擦傷和耐磨性。法蘭墊片采用複合材料,膨脹係數大,氣密性能(néng)好,保證係統與大氣隔離可靠。倒密(mì)封(fēng)采用不鏽鋼螺紋連接密封座或本體堆焊奧氏體不鏽鋼而成,倒密封可靠。填料更(gèng)換和維(wéi)修可在不停機情況下進行,方便快捷不影響係(xì)統運行

| 產品類型 | 殼體強度試驗(yàn)/MPa | 上密封試驗/MPa | 密封試驗/MPa | 適(shì)用介質 | 適(shì)用溫度/℃ |

| NKJ61H-40 | 6.O | 4.4 | 4.4 | 水、蒸汽、空氣 | ≤425 |

| NKJ61H-64 | 96 | 7.O | 7.O | ||

| NKJ61H-100 | 15.O | 11.0 | 11.O | ||

| NKJ61Y-40l | 6.O | 4.4 | 4.4 | 水、蒸汽(qì)、空氣 | ≤550 |

| NKJ61Y-64l | 9.6 | 7.0 | 7.O | ||

| NKJ61Y-1OOI | 15.O | 11.O | 11.O |

| 零件名(míng)稱 | 閥體、閥蓋 | 閥杆 | 閥瓣 | 密封麵 | 閥杆螺母 | 填料(liào) | 緊固件(jiàn) |

| NKJ61H-C型 | 25或WCB | 鉻不鏽鋼 | 鉻不鏽鋼 | H:合金(jīn)鋼 | 鋁青銅 | 膨脹複合石(shí)墨 | 優質碳(tàn)鋼 |

| NKJ61Y-l型 | 鉻鉬鋼 | 20CrlM01vA 或38CrMoAlA | 12CrlMo 1VA | Y:硬質合金 | 鉻(gè)鉬鋼 |

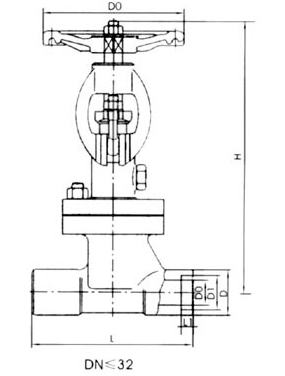

| 公稱通徑 DN/mm |

公稱壓(yā)力 PN/MPa |

主要外形尺寸和連接尺寸/mm | |||||||

| L | H | D | D0 | D1 | L1 | α | W | ||

| 1O | 4.0 | 130 | 245 | 36 | 11 | 18.4 | 1O | - | 120 |

| 15 | 130 | 245 | 36 | 16 | 22.5 | 1O | - | 120 | |

| 20 | 150 | 265 | 44 | 21 | 28.5 | 11 | - | 160 | |

| 25 | 160 | 270 | 48 | 26 | 34.5 | 12 | - | 200 | |

| 32 | 180 | 285 | 48 | 34 | - | - | 37o30’ | 200 | |

| 40 | 200 | 320 | 55 | 40 | - | - | 37o30’ | 240 | |

| 50 | 230 | 365 | 64 | 48 | - | - | 37o30’ | 320 | |

| 65 | 290 | 41O | 82 | 66 | - | - | 37o30’ | 300 | |

| 80 | 31O | 430 | 95 | 78 | - | - | 37o30’ | 300 | |

| 100 | 350 | 470 | 117 | 1OO | - | - | 37o30’ | 350 | |

| 125 | 400 | 500 | 143 | 126 | - | - | 37o30’ | 350 | |

| 150 | 480 | 533 | 167 | 150 | - | - | 37o30’ | 400 | |

| 1O | 6.4 | 130 | 245 | 36 | 1O | 18.4 | 1O | - | 120 |

| 15 | 130 | 245 | 36 | 15 | 22.5 | 1O | - | 120 | |

| 20 | 150 | 265 | 44 | 20 | 28.5 | 11 | - | 160 | |

| 25 | 160 | 270 | 48 | 25 | 34.5 | 12 | - | 200 | |

| 32 | 180 | 280 | 48 | 33 | - | - | 37o30’ | 200 | |

| 40 | 200 | 320 | 55 | 39 | - | - | 37o30’ | 240 | |

| 50 | 230 | 365 | 64 | 48 | - | - | 37o30’ | 320 | |

| 65 | 290 | 41O | 82 | 65 | - | - | 37o30’ | 320 | |

| 80 | 31O | 430 | 95 | 76 | - | - | 37o30’ | 360 | |

| 100 | 350 | 470 | 117 | 98 | - | - | 37o30’ | 400 | |

| 125 | 480 | 500 | 143 | 123 | - | - | 37o30’ | 400 | |

| 150 | 480 | 533 | 167 | 148 | - | - | 37o30’ | 500 | |

| 1O | 10.O | 130 | 245 | 36 | 1O | 18.4 | 1O | - | 120 |

| 15 | 130 | 245 | 36 | 14 | 22.5 | 1O | - | 120 | |

| 20 | 150 | 265 | 44 | 20 | 28.5 | 11 | - | 160 | |

| 25 | 160 | 270 | 48 | 25 | 34.5 | 12 | - | 200 | |

| 32 | 180 | 285 | 48 | 32 | - | - | 37o30’ | 200 | |

| 40 | 200 | 320 | 55 | 38 | - | - | 37o30’ | 240 | |

| 50 | 230 | 355 | 64 | 48 | - | - | 37o30’ | 320 | |

| 65 | 290 | 41O | 82 | 63 | - | - | 37o30’ | 320 | |

| 80 | 31O | 430 | 95 | 74 | - | - | 37o30’ | 360 | |

| 1OO | 350 | 470 | 117 | 97 | - | - | 37o30’ | 400 | |

| 125 | 400 | 500 | 143 | 123 | - | - | 37o30’ | 400 | |

| 150 | 480 | 533 | 167 | 148 | - | - | 37o30’ | 500 | |

注:PN4.0(40)閥門允許作為PN1.0(10)、PN1.6(16)、PN2.5(25)壓力級選用